Unlock Your PLC with IoT

Connect PLC systems directly to a database inside the same network to enable direct IoT data exchange. Our lightweight software enables quick and reliable data communication between a PLC system and a database over a network connection.

Currently available for Mitsubishi PLC systems to read and write data directly from/to the PLC memory.

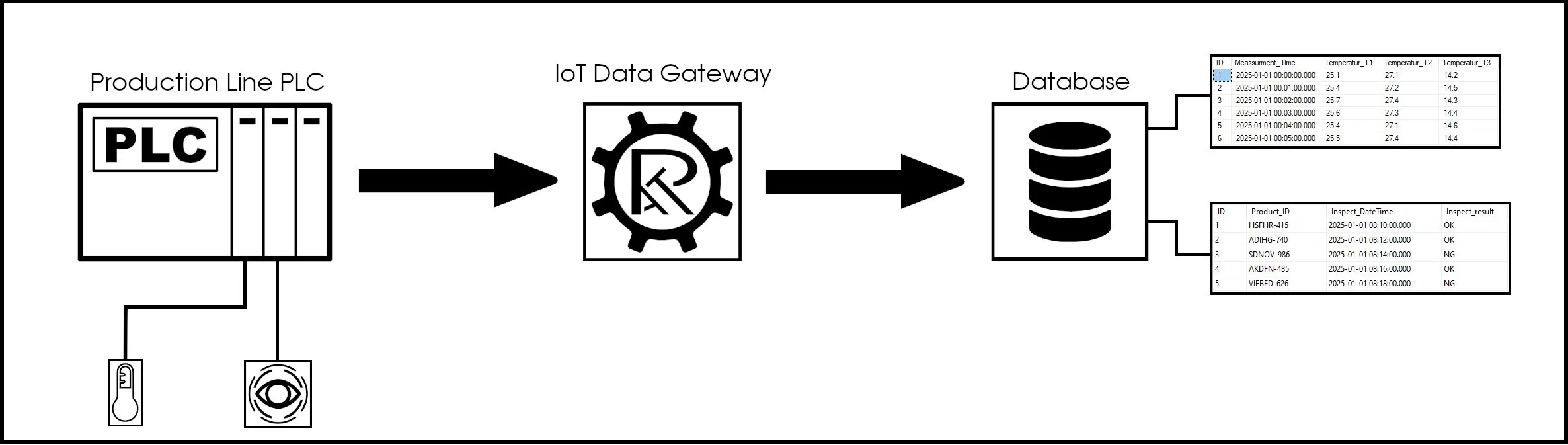

Read PLC data for database storage

Store PLC data in a database for production history analysis. From simple sensor information to complex production histories.

For example:

Store temperature sensor data periodically to analyze environmental factors

Store quality inspection data directly from production systems

Periodically store level sensor data to analyze raw material usage

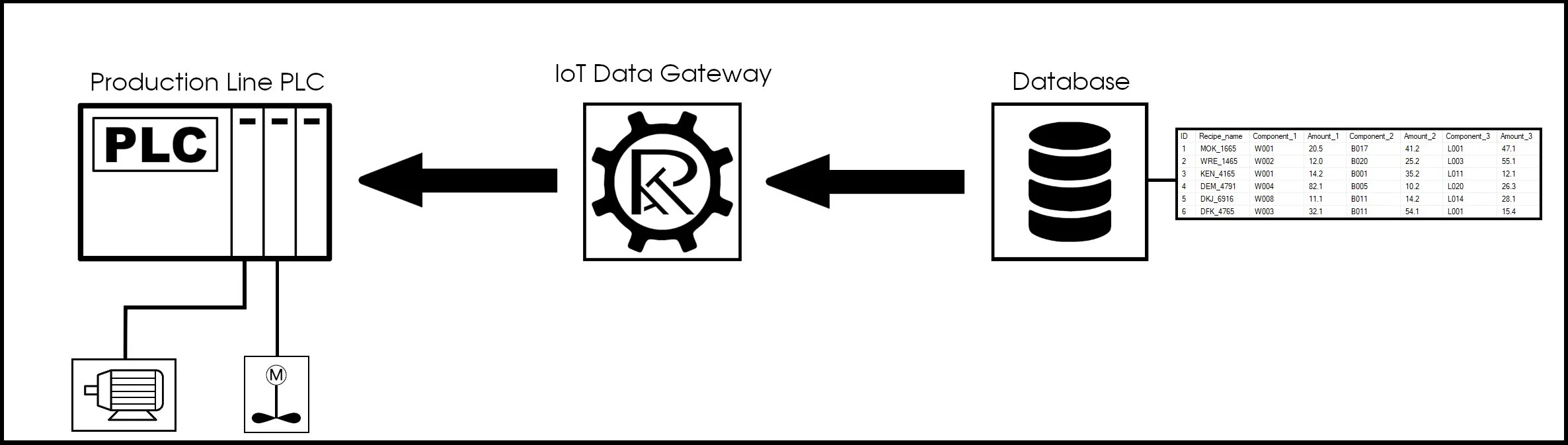

Send database information directly to PLC system

Send relevant production information from a database directly to the production level PLC.

For example:

Send recipe information from database to mixing machine PLC

Load product information from SAP system database into production level PLC

Transfer database information on PLC triggered events

Get Ready for AI-Automation

Start collecting AI-Training data of your manufacturing process for future AI automation models. In order for any AI model to achieve meaningful targets, a lot of actual process information is needed to train the AI for the best results. Our ‘IoT-Data Gateway’ allows for data collection of current production process information and store for future use of training an AI model.

Additionally, the ‘IoT-Data Gateway’ will convert the data into the required format for the database exchange to ensure data consistency between all involved IoT systems and to ensure ease-of-use for future applications.

Have any questions?

Feel free to contact us anytime

Riegler Automation Technology Co., Ltd.

28 F., No. 251, Minquan 1st Rd.,

Xinxing District, Kaohsiung City,

Taiwan